India is one of the world’s largest rice producers and exporters, delivering an enormous variety of rice — from the aromatic long-grain Basmati to high-yield non-Basmati and specialty rices (parboiled, white, brown, organic). For global buyers, sourcing rice from India offers competitive pricing, diverse product profiles, and large-scale production capacity. However, with opportunity comes responsibility: to secure quality, compliance, and reliable supply you must work with verified rice suppliers — exporters and brands who meet international food-safety standards, transparently document provenance, and demonstrate strong logistics and commercial track records.

This guide explains what “verified” means in practice, what global buyers should look for, how to evaluate suppliers and brands, contract and quality checkpoints, logistics and payment best practices, and a practical due-diligence checklist you can use right away.

1. The Indian rice landscape — quick overview

India produces a wide range of rice types. Understanding the categories helps you match product to market:

- Basmati rice: Long-grain aromatic rice grown primarily in the Indo-Gangetic plains (Punjab, Haryana, Delhi, Uttarakhand, parts of western Uttar Pradesh). Valued for aroma, elongation on cooking, and premium markets.

- Non-Basmati white rice: Short- to medium- and long-grain varieties used widely in Africa, Southeast Asia, Middle East, and domestic markets.

- Parboiled rice: Steam-treated rice with improved shelf life and higher nutrient retention, popular in West Africa and parts of Asia.

- Brown rice / whole grain: Health-focused markets demanding minimally processed rice.

- Specialty & organic rice: Single-origin, heirloom varieties, scented/colored rice, and certified organic rice for premium health-conscious consumers.

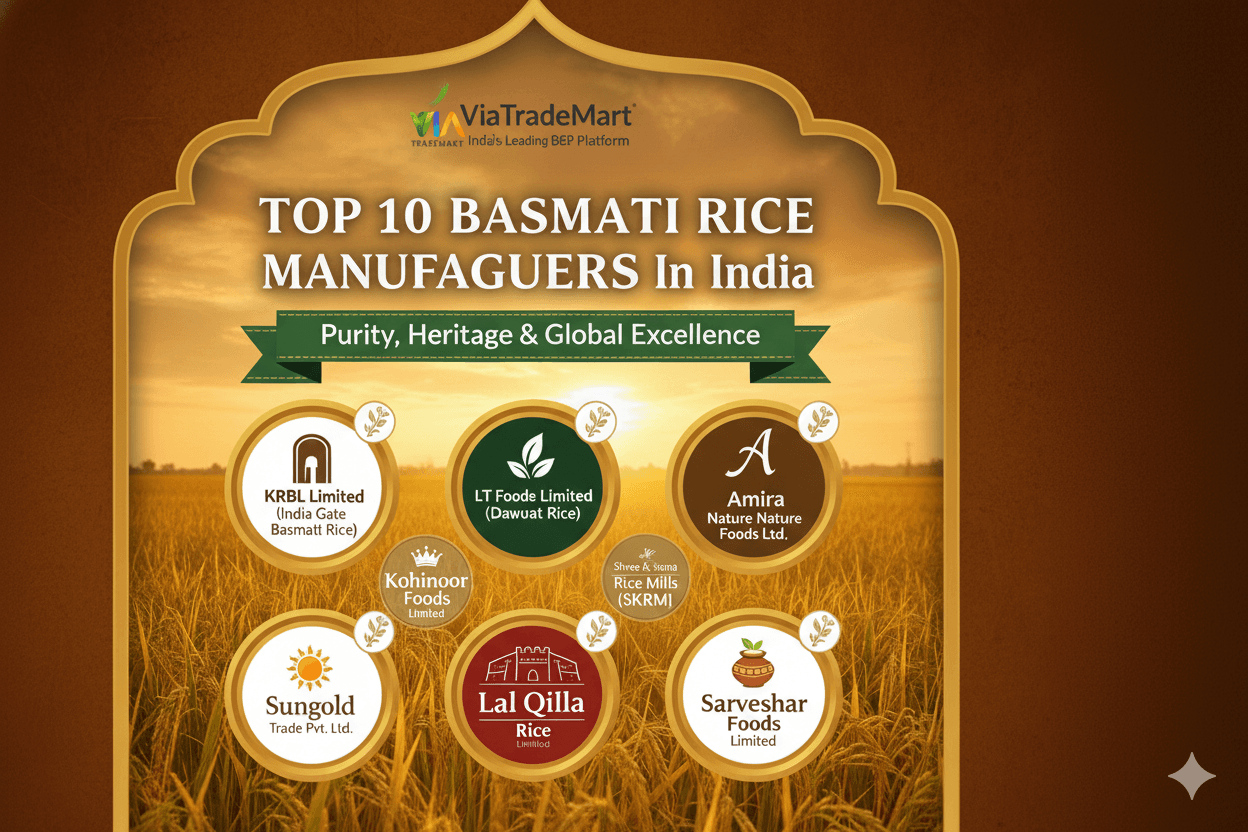

Major rice-producing states include Uttar Pradesh, West Bengal, Punjab, Andhra Pradesh, Telangana, Chhattisgarh, Odisha and Bihar. Exporters vary widely — from large integrated agribusinesses and mills to specialized packers and farmer cooperatives.

2. What does “verified supplier” mean?

A verified rice supplier is more than a company with a web page. For global trade, verification covers multiple layers:

- Regulatory compliance — Up-to-date registrations, permits, and certifications (export license, FSSAI registration for food safety in India, AGMARK where applicable).

- Third-party certifications — ISO, HACCP, BRC, SQF, Organic (USDA/India Organic), Fair Trade or other recognized standards.

- Product testing and traceability — Lab analyses for moisture, broken percentage, foreign matter, pesticide residues, heavy metals, and GMO status; batch-level traceability from field to pack.

- Supply chain transparency — Clear packaging specifications, mill/warehouse visits allowed, photographs of facilities, and shipment track records.

- Financial and legal credibility — Verified business registration, GST / tax records, bank references, consistent trade history and positive trade references from past buyers.

- Quality management systems — Written quality policy, SOPs for sampling, QC lab or third-party labs, and recall plans.

As a buyer, require evidence across these dimensions and make the verification process part of your supplier onboarding.

3. Certifications and paperwork to request (non-negotiable)

When assessing a supplier, demand the following documents and verify them independently where possible:

- Business documents

- Certificate of Incorporation / Business Registration

- GST registration (India) / PAN

- IEC (Import Export Code) for exporters

- Company profile, number of employees, and factory/mill address

- Food safety & quality certificates

- FSSAI license (India)

- AGMARK certificate (where applicable)

- ISO 22000 / ISO 9001 (quality management)

- HACCP / BRC / SQF (food safety)

- Organic certification (USDA NOP / India Organic / EU Organic) for organic rice

- Lab & quality reports

- Recent SGS / Intertek / Bureau Veritas test reports (moisture, broken %, foreign matter, mycotoxins, pesticide residues)

- Phytosanitary certificate (issued by Indian authorities)

- Certificate of Origin for customs and trade preferences

- Export & logistics

- Copy of previous Bills of Lading / Airway Bills or proof of shipment (redact commercial details if needed)

- Insurance certificates (cargo)

- Packaging & labeling specifications (carton weight, inner liner, labeling language)

- Commercial

- Proforma invoice and payment terms

- Trade references and buyer contacts (ideally global buyers you can call)

Always cross-check certificates with issuing bodies and ask for originals or verified electronic copies when needed.

4. Key rice quality parameters and acceptable ranges

Understanding measurable rice attributes lets you write precise specifications:

- Moisture content: Typically 12–14% for export-grade rice; lower moisture is better for shelf life and reduces risk of spoilage.

- Broken rice percentage: Premium whole-grain rice (eg. extra-long Basmati) often <1–2% broken; standard export grades may permit 2–8% broken depending on grade.

- Test weight / density: Indicates quality and kernel integrity — commonly measured as kg/hl or g/100 grains depending on the lab.

- Amylose content: Affects cooking behavior; basmati often medium-high amylose for fluffiness.

- Foreign matter & stones: Should be negligible (0.1% or as per contract).

- Chalkiness: Low chalkiness preferred for premium rice.

- Aroma & elongation (for Basmati): Basmati aroma and elongation ratio (length after cooking / raw length) are critical commercial metrics.

- Mycotoxins & pesticide residues: Must meet buyer-country MRLs (maximum residue limits). Include specific tests in contract.

- GMO status: Declare if any genetic modification used; many buyers require non-GMO declarations.

Include an agreed testing laboratory and sampling method in the contract (e.g., sampling at loading using ISO sampling standards, tested by SGS).

5. How to verify supplier claims (practical steps)

- Request verifiable documentation (certificates, test reports) and validate them with issuing bodies or third-party verification platforms.

- Third-party inspection at origin — Before shipment, hire a recognized inspection agency (SGS, Intertek, BV) for on-site inspection and pre-shipment sampling.

- Factory/mill visits — If feasible, visit the milling & packaging unit or arrange a virtual factory tour (video call showing production lines, storage silos, packaging lines).

- Ask for references and contact them — Speak to past buyers about lead times, quality consistency, and claim resolution.

- Request samples & lab test with your own lab — Do independent testing before accepting bulk shipments.

- Check trade history — Review export data where public (trade databases) or ask supplier for past shipment manifests.

- Verify bank references and financial standing — This reduces risk of last-minute cancellations.

6. Packaging, labeling and shelf life considerations

Packaging matters for preservation and market acceptability:

- Inner packing: Food-grade polyethylene (PE) or poly-laminated liners inside jute, woven polypropylene (PP) sacks, or distinctive retail pouches (e.g., 5kg, 10kg, 25kg).

- Vacuum / modified atmosphere: For extended shelf life or export to humid climates, consider nitrogen-flushed bags or moisture barrier laminates.

- Net weight & tare: Ensure accurate net weight (e.g., 50 kg ±0.5 kg) and specify tolerances in the contract.

- Labeling: Must meet buyer-country regulations — ingredients, origin, batch/Lot number, production & best-before dates, nutritional information (if retail), and storage instructions.

- Shelf life: Typically 12–24 months depending on variety and packaging. Specify accepted shelf life at time of loading (e.g., minimum 12 months remaining).

Consider sample retail packaging, barcode/QR code inclusion, and private-labeling needs early in negotiations.

7. Pricing, payment terms, and cost components

Rice pricing depends on many variables — variety, grade, seasonality, global demand, freight and insurance, and currency fluctuations. Key cost components:

- Ex-factory / Mill price — base price for rice per metric ton (MT).

- Packing & value-add — sorting, polishing, aroma enhancement (for some rices), retail packaging.

- Quality premium — extra for low broken %, organic, or specialty single-origin rice.

- Logistics — inland transport to port, port handling, container stuffing, FOB/CIF/EXW terms affect buyer/seller allocation of costs.

- Freight & insurance — container shipping or bulk vessel rates; affected by season and global freight market.

- Customs and duties — export duty (rare on rice from India), import duties in buyer country, port charges.

- Testing & inspection fees — third-party pre-shipment inspection and testing.

Common payment terms:

- TT in advance (Telegraphic Transfer) — full or partial upfront.

- LC at sight (Letter of Credit) — widely used for first-time high-value transactions; reduces buyer risk if drafted properly.

- Usance LC or DP/DA — deferred payment options negotiated with trust.

- Open account — for trusted long-term partners.

Negotiate terms based on risk profile. For first shipments prefer LC or partial advance + balance on B/L.

8. Shipping, logistics and Incoterms

Choose Incoterms that define responsibilities clearly:

- FOB (Free on Board) — Seller arranges goods to vessel at named port; buyer pays freight and insurance.

- CIF (Cost, Insurance & Freight) — Seller covers freight and minimum insurance to destination port; buyer handles import formalities.

- EXW / DAP / DDP — progressively shift responsibilities to buyer or seller; DDP includes import duties and is seller-heavy.

Practical logistics tips:

- Containerization — Rice is generally exported in 20ft or 40ft containers (bagged and palletized to prevent shifting). Container stuffing must follow hygiene and fumigation standards.

- Bulk shipments — For very large orders, bulk shipments via covered vessels may be possible — verify port handling and discharge facilities.

- Transit time & cold chain — Rice does not need cold chain but avoid humid transit. Use moisture-absorbing desiccants when necessary.

- Insurance — Always insure cargo to agreed value (CIF implies seller arranges minimal insurance; buyers often arrange more comprehensive coverage).

- Customs clearance — Provide proper documentation: commercial invoice, packing list, certificate of origin, phytosanitary certificate, and test reports.

9. Risk management & dispute resolution

Common risks: quality mismatch, delayed shipments, regulatory rejection at destination, and payment disputes. Mitigation strategies:

- Pre-shipment inspection — makes disputes rare and easier to resolve.

- Quality clauses in contract — define acceptable ranges, testing labs, sampling methods, and arbitration mechanisms.

- Insurance & indemnity — cargo insurance; seller warranties on quality & compliance.

- Escrow / LC — minimizes payment risk.

- Arbitration clause — choose neutral jurisdiction or internationally recognized arbitration (ICC/LCIA) and a governing law both parties accept.

- Force majeure — standard clause covering natural disasters, strikes, government action.

Document every step and keep communication transparent.

10. How to assess a brand’s trustworthiness without visiting

For buyers who can’t travel, these remote checks help:

- Public reviews & trade references — online B2B platforms often include buyer feedback; cross-check.

- Third-party inspection certificates — authentic SGS / Intertek reports tied to lot numbers.

- Video verification — live video tours of mills, storage, and factory lines during operating hours.

- Request audited financials — basic financial health indicators.

- Ask for independent lab testing — buyer commissions test on samples sent to the buyer’s trusted lab before bulk shipment.

- Check regulatory databases — verify FSSAI/ISO via issuing agencies’ databases.

Use multiple methods in combination to reduce risk.

11. Red flags to watch for

- Reluctance to provide test reports or references.

- Certificates with inconsistencies or unverifiable issuing details.

- Pressure to accept samples that look great visually but without lab tests.

- Unwillingness to agree to third-party pre-shipment inspection.

- Unrealistically low prices for premium grades.

- Frequent changes in company address or contact details.

- Requests for unconventional payment methods or moving funds to personal accounts.

If you encounter multiple red flags, pause and re-evaluate.

12. Contract clauses to include (sample checklist)

- Product definition & grade (clear SKU, variety, broken %, moisture content, etc.)

- Quantity & tolerance (e.g., 1,000 MT ±5%)

- Price & currency (include currency and method to handle exchange rate fluctuations if long-term)

- Packaging & labeling requirements

- Sampling & testing protocol (point of sampling, lab, acceptance criteria)

- Delivery terms & Incoterm

- Payment terms (LC details, advance %, timelines)

- Insurance & risk transfer

- Force majeure

- Dispute resolution & governing law

- Warranty & indemnity

- Penalties for non-conformance or late delivery

- Quality retention samples (retain samples for agreed period)

A clear contract prevents most disputes.

13. Working with different buyer profiles (retailer, wholesaler, food processor)

- Retailers / FMCG brands: Require retail-ready packaging, branding, traceability, nutritional facts, and long-term supply contracts with predictable quality.

- Wholesalers / distributors: Need competitive FOB/CIF pricing and flexible minimum order quantities; sometimes accept higher broken % depending on downstream processing.

- Food processors / mills: May buy specific grades for blending or parboiling and require large volumes and consistent lot qualities.

- Institutional / humanitarian buyers: Focus on shelf life, fortification (if required), and strict compliance to tender specifications.

Tailor specs and commercial terms according to buyer needs.

14. Sustainability, ethics, and social compliance

Increasingly, global buyers expect sustainable sourcing:

- Sustainability certifications: Rainforest Alliance, Fairtrade, or specialized water-use/soil health certifications (where available).

- Labor compliance: Supplier audits covering worker wages, hours, safety, and child labor prevention.

- Environmental footprint: Consider water-use efficiency (paddy rice is water-intensive), use of sustainable irrigation, and fertilizer/pesticide reduction programs.

- Traceability & farmer support: Suppliers that source through farmer groups or cooperatives and provide support programs for farmers often offer more stable supplies and verifiable origins.

Ask suppliers about sustainability programs and request evidence of audits and initiatives.

15. Sample onboarding flow for a new supplier (practical timeline)

- Introduction & NDA — Exchange company details and sign confidentiality where necessary.

- Initial document submission — Business registration, FSSAI, IEC, product specs.

- Sample order — Request sample with full packaging and lab test reports.

- Independent lab test — Buyer sends sample to a designated lab.

- Reference checks & inspections — Contact references and arrange third-party pre-shipment inspection if sample is approved.

- Commercial negotiation & contract signing — Confirm price, INCOTERMS, LC or payment terms.

- Pilot shipment — Small shipment to validate full process (logistics, customs, packaging).

- Full commercial shipments — If pilot succeeds, move to larger volumes and consider framework agreements for stable pricing.

This staged approach balances speed with risk mitigation.

16. Frequently asked questions (FAQs)

Q: How many suppliers should I vet before picking one?

A: Vet at least 3–5 suppliers to compare quality, pricing, and responsiveness. This provides negotiating leverage and fallbacks.

Q: Is it safe to rely on certificates provided by the supplier?

A: Treat supplier-provided certificates as initial evidence. Independently verify where possible or request third-party verification.

Q: What is a reasonable lead time for shipments from India?

A: Lead time varies by season, port congestion and contract terms. For container shipments, typical lead time is 2–6 weeks from order confirmation to port loading (excluding sea transit). For bulk shipments timelines differ. Always confirm with supplier and logistics provider.

Q: How do seasonal fluctuations affect rice quality and price?

A: Harvest seasons and stock levels influence price and moisture. During peak harvest, you may get better pricing but must manage moisture and storage to avoid quality issues.

Q: Should I require a retention sample?

A: Yes — ask sellers to retain a sealed stock sample for the batch for a specified period (e.g., 6–12 months) to resolve disputes.

17. Due-diligence checklist (printable)

Use this checklist when evaluating any potential rice supplier:

Company Verification

- Company registration and IEC copy obtained

- GST / tax ID checked

- Trade references obtained and contacted

Quality & Certifications

- FSSAI / AGMARK copy verified

- ISO / HACCP / BRC copies received

- Organic certificate (if applicable) checked

- Sample lab test (SGS/Intertek/BV) provided

- Batch traceability (Lot no., date, source) documented

Product Specs

- Variety and grade clearly defined (Basmati/Non-Basmati/Parboiled)

- Moisture % acceptable

- Broken % acceptable

- Packaging & net weight specifications agreed

Logistics

- Incoterms and port defined

- Freight & insurance responsibilities clear

- Pre-shipment inspection agreed (agency & criteria)

- Phytosanitary and Certificate of Origin required

Commercial

- Price per MT or per carton agreed

- Payment terms and currency set

- Delivery schedule and penalties for delays

Legal & Risk

- Arbitration & dispute resolution clause

- Force majeure defined

- Recall & indemnity clauses included

Checking each item reduces the risk of surprises.

18. Practical templates (short & useful)

Sample initial email to request verification documents

Subject: Request for Verification Documents — [Your Company] / [Rice Variety]

Hello [Supplier Name],

Thank you for the quotation. To proceed, please share scanned copies of the following documents for verification: Company registration, IEC, FSSAI, recent third-party lab test (SGS/Intertek), ISO/HACCP certificate (if any), sample packing photos, and three trade references. Also confirm typical lead time and available monthly volumes.

Regards,

[Your name, title, company]

Sample specification snippet (to include in contract)

Product: India Long Grain Basmati Rice — Extra Long Aged

Quantity: 500 MT ±5%

Moisture: ≤ 12.5% at time of dispatch

Broken: ≤ 1.5%

Packaging: 50 kg poly-laminated PP sacks with inner PE liner, 20 sacks per pallet, sealed with heat seal.

Sampling: ISO 6644 sampling method at loading. Laboratory: SGS Mumbai. Acceptance: SGS report within contract parameters.

19. Market trends & strategic considerations (buyer-focused)

- Premiumization: Demand for authentic single-origin basmati and organic rice is growing in premium markets.

- Health & convenience: Brown rice, parboiled, and value-added ready-to-cook rice products are in demand.

- Traceability: Consumers and regulators increasingly want clear origin data; invest in suppliers who can deliver traceability.

- Vertical partnerships: Consider long-term contracts with farmer groups or integrated mills to secure stable supply and preferred pricing.

- Technology: Blockchain pilots and IoT in warehouses are emerging to improve traceability and quality monitoring.

When sourcing for long-term market entry, align procurement strategy with these trends.

20. Conclusion — getting started now

Sourcing rice from India is highly attractive but requires rigorous verification to ensure product safety, quality and reliable delivery. Prioritize suppliers who provide verifiable documentation, accept third-party inspections, and demonstrate transparent traceability from farm to pack. Use a staged onboarding process — sample, inspect, pilot shipment — before committing to large volumes. Include clear contractual quality parameters and dispute mechanisms.